|

| March 07, 2017 | Volume 13 Issue 09 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Hyperloop Tech: How does a linear induction motor work?

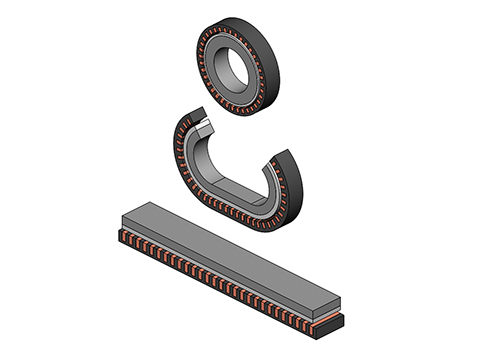

Linear induction motor (LIM) theory is most easily understood as a rotary motor that has been cut and unrolled to generate linear motion, instead of rotary motion. It is comprised of two parts, the primary and secondary, which interact with one another only when power is applied. Either the primary or the secondary can be fixed while the other moves.

When three-phase AC power is applied to the primary, a travelling electromagnetic flux wave is induced and moves relative to the primary. The wave induces an electric current in the conductive reaction plate. The induced electric current interacts with the magnetic flux to produce a linear force. The speed of the motor can be varied by changing the input frequency using an adjustable frequency drive.

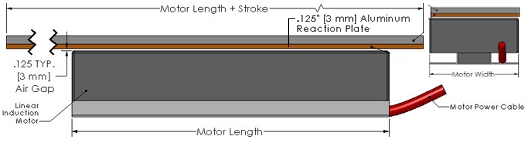

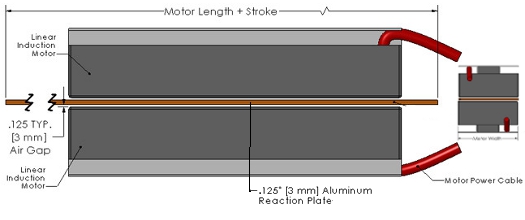

The primary consists of a three-phase coil assembly, equivalent to the stator of a rotary motor. The three-phase coils are wound and inserted into a steel lamination stack along with thermal protection components. The coil windings and stack are then encapsulated in a thermally conductive epoxy.

The secondary, known as a rotor in a traditional rotary induction motor, is a reaction plate. This plate can be comprised of aluminum or copper, and a steel backing. The reaction plate length is equal to the length of the coil plus the stroke. A bearing system is required to maintain the air gap between the primary and secondary.

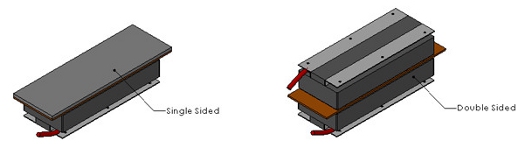

Linear induction motors can be manufactured in a wide range of force outputs, speeds, and footprints. For single-sided assemblies, the reaction plate consists of 1/8-in.-thick aluminum backed by a 1/4-in.-thick steel plate, and for double-sided assemblies the reaction plate is 1/8-in.-thick aluminum or copper only. If the reaction plate is round and it has a center shaft with rotary bearings, the system will produce rotary motion.

Single-sided.

Double-sided.

Why use a linear induction motor?

Linear induction motors are ideal for applications that require rapid movement of large payloads. Linear induction motors can achieve speeds in excess of 1,800 in./sec (45 m/s) and accelerations in the range of 3 to 4 g. Standard LIMs can produce forces in the range of 720 lb (3,200 N) at a 3% duty cycle. Multiple motors can be used in conjunction with each other to generate larger forces.

Linear induction motor applications

LIMs can be found in theme park rides, water rides, people-moving systems, high-speed transportation, and maglev propulsion applications. Here are some well-known examples:

Hyperloop

Hyperloop is a high-speed transport system for passengers and goods, incorporating reduced pressure tubes, pressurized pods, linear induction motors, and air compressors. Linear induction motors are used to propel and decelerate the pods over the tracks and through the tubes. The LIMs are reversible, so the same motor that propels the pod in one direction down the track can be used to propel the pod back to where it started. The pods could potentially "float" on an air bearing to eliminate friction.

VIDEO: CNBC International -- Watch how the Hyperloop uses magnets to move at 760 mph.

VIDEO: CNN Money: 700 mph in a tube -- The Hyperloop experience.

Big Thunder Mountain Railroad at Disneyland Resort

Big Thunder Mountain Railroad is one of the first roller coasters to use linear induction motors to accelerate cars out of the station. This allows the cars to start moving at high speeds from a stationary state, without the typical hill-and-chain start. The LIMs are also used to park cars in storage.

California Screamin at Disneyland Resort

California Screamin utilizes LIMs to launch the cars of the roller coaster. They are used again further into the ride to accelerate the cars as they travel over the hills.

Tomorrowland Transit Authority at Walt Disney World, Magic Kingdom Park

Linear induction motors power Tomorrowland Transit Authority (formerly known as the People Mover), moving large cars at smooth, slow speeds through Tomorrowland.

Dawwama at Yas Waterworld Abu Dhabi, Yas Island

The first section of Yas Island's Dawwama water coaster is powered by LIMs. At each of the hills, the linear induction motors launch the tubes through the uphill sections. This method of propulsion in water coasters is called hydromagnetic technology.

Thunder Rapids in White Water Bay, Six Flags Fiesta, Texas

Thunder Rapids, to open in 2017, will be the first water coaster is the USA to utilize hydromagnetic technology. Linear induction motors are combined with turbine technology to keep the tube speeding along the slide and over the hills.

H2w Technologies is dedicated to the design and manufacture of linear and rotary motion products that are used in the motion control industry.

Source: H2w Technologies

Published March 2017

Rate this article

View our terms of use and privacy policy